Sanded vs. Unsanded Drywall Finishing: Unlock Savings of Up to $800

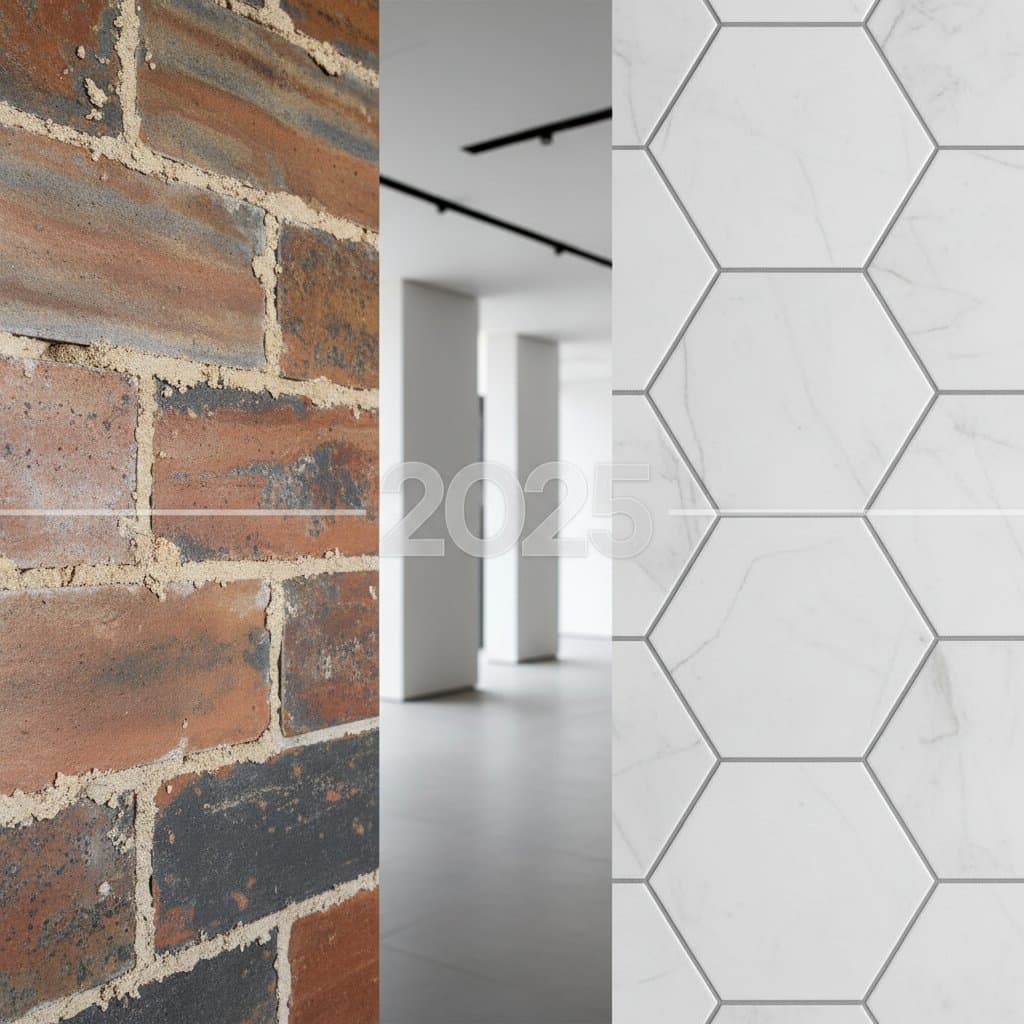

Homeowners frequently overlook the finishing stage of drywall installation, yet this step profoundly influences the final appearance and overall project expenses. Sanded finishes provide a sleek, uniform surface that enhances contemporary designs, while unsanded options introduce texture to conceal minor defects at a lower price point. Grasping these distinctions enables informed decisions that align with aesthetic preferences and financial constraints.

Drywall finishing expenses fluctuate based on scope and method, generally spanning $1.50 to $3.50 per square foot for materials, labor, and associated tasks. For a typical room, anticipate costs from $800 to $2,000. Identifying key cost drivers ensures efficient budgeting and avoids overruns while preserving professional results.

Project Cost Ranges by Room Size

- Small room (approximately 200 square feet): $300 to $700

- Medium room (approximately 400 square feet): $700 to $1,400

- Large room (approximately 600 square feet): $1,200 to $2,000

Per-Square-Foot Cost Components

Drywall finishing averages $1.50 to $3.50 per square foot, broken down as follows:

- Materials: $0.50 to $1.20 per square foot

- Labor: $0.80 to $2.00 per square foot

- Preparation and cleanup: $0.20 to $0.30 per square foot

- Additional elements: $0.10 to $0.50 per square foot, varying with texture intricacy

Labor demands and preparation efforts primarily differentiate sanded from unsanded approaches, directly impacting total expenditures.

Key Features of Sanded Drywall Finishing

Sanded drywall finishing yields a flawless, level surface suited to minimalist or modern environments. Professionals apply joint compound in layers, sanding meticulously after each to eliminate bumps and inconsistencies. This technique produces walls that diffuse light uniformly, complementing high-gloss or semi-gloss paints.

Process elements include:

- Several applications of joint compound

- Thorough sanding between layers

- Dust mitigation and priming prior to painting

Financial implications:

Precision sanding elevates labor charges by $0.50 to $1.00 per square foot. In a 400-square-foot area, this increment translates to $200 to $400 beyond unsanded alternatives.

Benefits:

- Exceptionally even texture

- Optimal for luminous paint applications

- Enhances market value in luxury residences

Limitations:

- Elevated labor expenses

- Extended timeline

- Increased dust generation and subsequent cleaning

Key Features of Unsanded Drywall Finishing

Unsanded drywall finishing, commonly known as skip-trowel or textured application, forgoes intensive sanding to emphasize surface variation. This approach employs tools like trowels or sprayers to build subtle patterns that obscure seams and irregularities. It proves advantageous in expansive areas, basements, or overhead installations where texture contributes visual interest.

Process elements include:

- Reduced layers of joint compound

- Limited or absent sanding

- Texture imposition via specialized implements

Financial implications:

Such finishes range from $1.00 to $2.50 per square foot, potentially yielding $800 in savings for comprehensive home projects relative to sanded methods.

Benefits:

- Reduced labor outlay

- Accelerated project pace

- Effective concealment of surface anomalies

Limitations:

- Challenging subsequent repairs

- Restricted compatibility with certain paints

- Potential for dust or humidity accumulation in textured profiles

Influences on Drywall Finishing Expenses

Multiple elements determine whether a project adheres to or surpasses budgetary limits.

1. Surface Dimensions and Configuration

Expansive areas demand greater resources. Features like arched ceilings or numerous angles extend labor by 20 to 30 percent.

2. Selected Finish Style

Polished surfaces necessitate extensive sanding and adjustments. Textured variants require fewer refinements but specialized equipment.

3. Material Specifications

Superior joint compounds enhance longevity yet raise costs marginally, adding about $0.25 per square foot.

4. Contractor Expertise and Rates

Charges reflect proficiency and locale. Skilled workers command higher fees but minimize errors and revisions.

5. Pre-Finishing Preparations

Addressing prior damage or irregularities may incur $100 to $300 extra.

6. Location and Timing Variations

High-demand regions inflate prices seasonally. Off-peak periods often yield availability and reduced rates.

Comparative Cost Breakdown by Finish

| Finish Type | Basic Range | Standard Range | Premium Range | Primary Distinctions |

|---|---|---|---|---|

| Sanded Finish | $1.80 - $2.50 | $2.50 - $3.00 | $3.00 - $3.50 | Sleek appearance boosting resale potential |

| Unsanded Finish | $1.00 - $1.50 | $1.50 - $2.00 | $2.00 - $2.50 | Patterned texture for quick, flaw-hiding setup |

Opting for unsanded textures across several rooms can curtail overall costs by $800 to $1,000, particularly in sizable renovations or builds.

Assessing Value and Long-Term Returns

Sanded finishes attract purchasers seeking pristine, contemporary vibes and integrate seamlessly with sheen-heavy paints that accentuate details. Though pricier, they elevate home appeal in vibrant markets.

Unsanded alternatives deliver resilience and flaw coverage with ease of maintenance. They suit utilitarian spaces like basements or investments, providing enduring benefits where perfection ranks secondary.

Practical Ways to Minimize Expenses

Strategic choices trim costs while upholding standards.

- Bundle drywall tasks with painting for consolidated discounts.

- Perform initial preparations, such as furniture relocation and floor protection.

- Apply selective sanding to prominent walls, texturing ancillary surfaces.

- Procure supplies in volume for multi-room endeavors.

- Time projects for contractor off-seasons to secure favorable bids.

Implementing these tactics often shaves hundreds from the budget.

Establishing a Realistic Budget

Calculate wall and ceiling square footage, then apply per-square-foot rates for each finish to forecast totals. Incorporate a 10 to 15 percent contingency for contingencies like additional materials or refinements.

For imminent painting, solicit integrated estimates encompassing both phases; contractors frequently discount bundles by 5 to 10 percent. Examine portfolios and credentials to verify alignment with envisioned outcomes.

Selecting the Right Drywall Finish

Sanded options excel in illuminated, focal areas like living spaces or foyers. Unsanded textures fit overheads, storage zones, or stylistic motifs embracing irregularity.

Consider these aspects:

- Illumination levels and exposure

- Intended paint sheen

- Available project duration

- Financial parameters and value enhancement goals

This evaluation promotes expenditure efficiency alongside aesthetic fulfillment.

Frequently Asked Questions

1. What constitutes the typical cost variance between sanded and unsanded drywall finishing?

Sanded processes range from $1.80 to $3.50 per square foot, contrasted with $1.00 to $2.50 for unsanded. A medium-sized room might differ by $200 to $400, escalating to $800 or beyond for whole-home applications.

2. Which elements most significantly affect drywall finishing costs?

Surface extent, finish variety, regional labor rates, and preparatory demands exert the greatest influence. Elaborate designs or elite supplies further elevate figures, with smooth variants amplifying sanding durations.

3. In what ways can expenses be reduced on drywall finishing while preserving quality?

Undertake preliminary tasks independently, align with low-demand periods, and texture non-prominent zones. Soliciting varied proposals and bulk acquisitions further economize.

4. Is it advisable to engage professionals or pursue drywall finishing as a DIY endeavor?

Professionals ensure uniformity and efficiency, particularly for expansive or intricate projects, justifying their fees through reduced errors and warranties. DIY suits minor repairs in accessible spaces but demands tools, time, and skill to avoid subpar results that incur future corrections.

5. How should one allocate funds for unforeseen drywall finishing expenses?

Build a 10 to 15 percent reserve atop baseline estimates to cover surprises like structural fixes or material shortages. Track expenditures progressively and prioritize essentials to manage variances effectively.

6. When does initiating drywall finishing yield the most economical outcomes?

Off-peak seasons, such as late fall or winter, typically offer contractor availability and competitive pricing due to diminished demand. Advance planning secures these advantages without rushing quality.